Features & Benefits

- Grade ‘A’ Safety Glass per AS2208:2023 Safety glazing materials in buildings;

- Depending on impact will not splinter into jagged pieces and will remain intact in the opening;

- Wide range of applications to suit energy, acoustics, decorative, strength and safety.

Applications

Residential and commercial glazing.

Range

Available 6.38mm to 33.52mm thickness.

Size Limits*

Maximum Size – 5000mm x 2600mm

Minimum Size –

- Cutting from stock sheets - 260mm measuring across the diagonal or 250mm x100mm for flat ground and polished edges;

- Custom laminated – minimum dimension 400mm x 400mm or 1000mm x 200mm.

*subject to inhouse manufacturing limitations per given thickness, types and design specifications.

Design & Glazing Notes

For energy efficiency solutions, select either SOL-R™ or Sunergy® low-E glass types. For noise reduction, select Acousta™ laminated glass. For structural and strength applications, both panels can be either heat strengthened or toughened with thicker and stronger interlayers such as SentryGlas® (SGP) or DG41. Decorative elements can be added with Vanceva® coloured interlayers and ImageTek™ceramic ink printed panels. For more details refer to Laminated Glass Design & Glazing Notes (Download).

How to Specify

- Specify National Glass Laminated Safety Glass;

- Select appropriate thickness and glass type;

- Single annealed laminated, heat strengthened, toughened, toughened heat soaked laminated or in an IGU;

- Energy requirements – select SOL-R™, SOL-XT™ or Sunergy® laminated low-E glass;

- Acoustic requirements – select Acousta™ laminated glass;

- Strength requirements – depending on application, select either heat strengthened or toughened laminated using SentryGlas® (SGP) or DG41 interlayers;

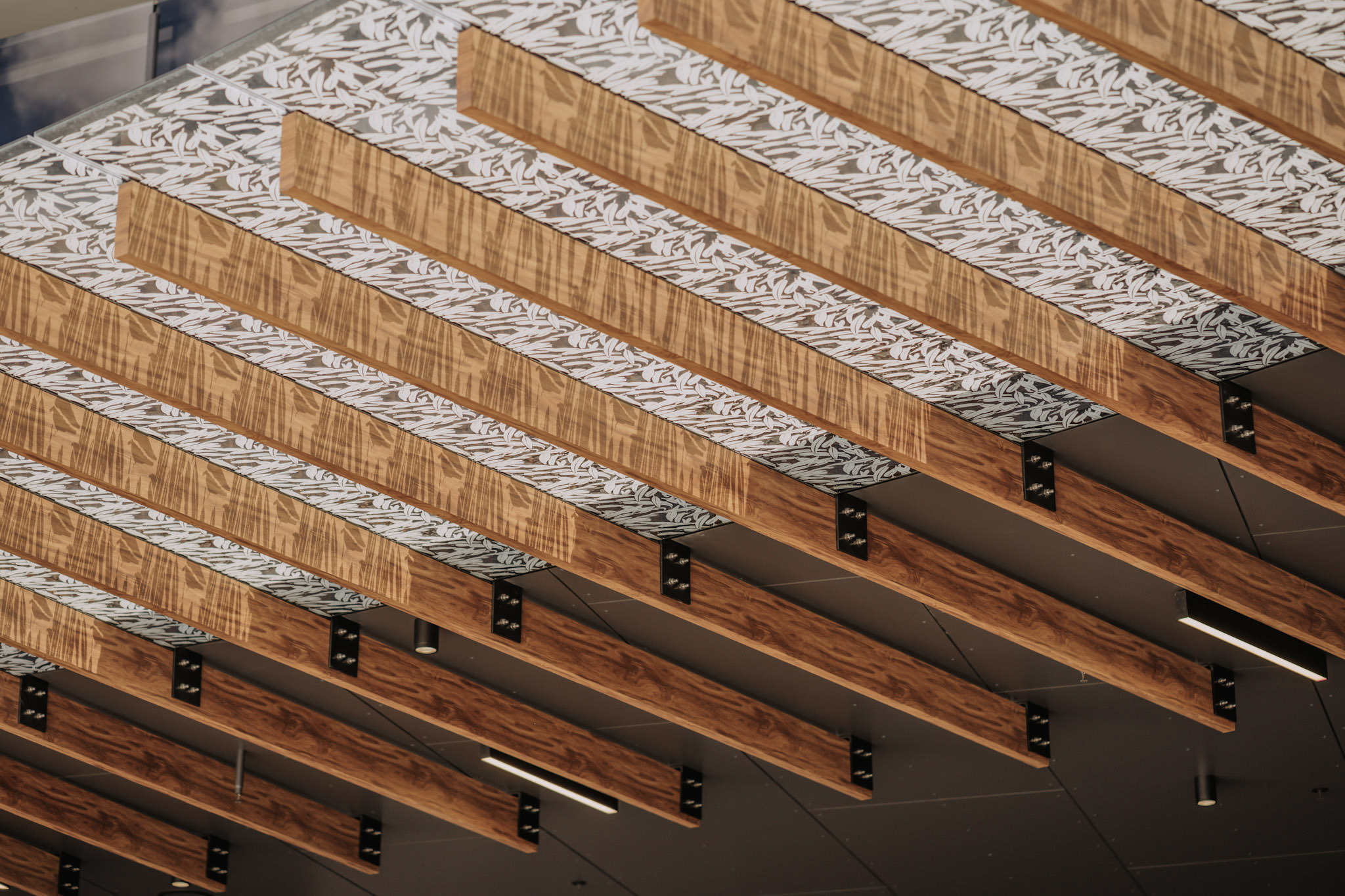

- Decorative applications – select Vanceva® coloured laminated glass or ImageTek™ ceramic ink printed panel options;

- All glass to be selected and installed in accordance but not exclusively to the following Australian Standards;

AS 1288 Glass in buildings – Selection and installation

AS 2208 Safety glazing materials in buildings

AS 4666 Insulating glass units

AS/NZS 4667 Quality requirements for cut-to-size and processed glass

AS 1170 Wind & Structural Design Actions